Multidirectional Scaffolding System

Home / Products / Multidirectional Scaffolding System / Ringlock System Scaffolding

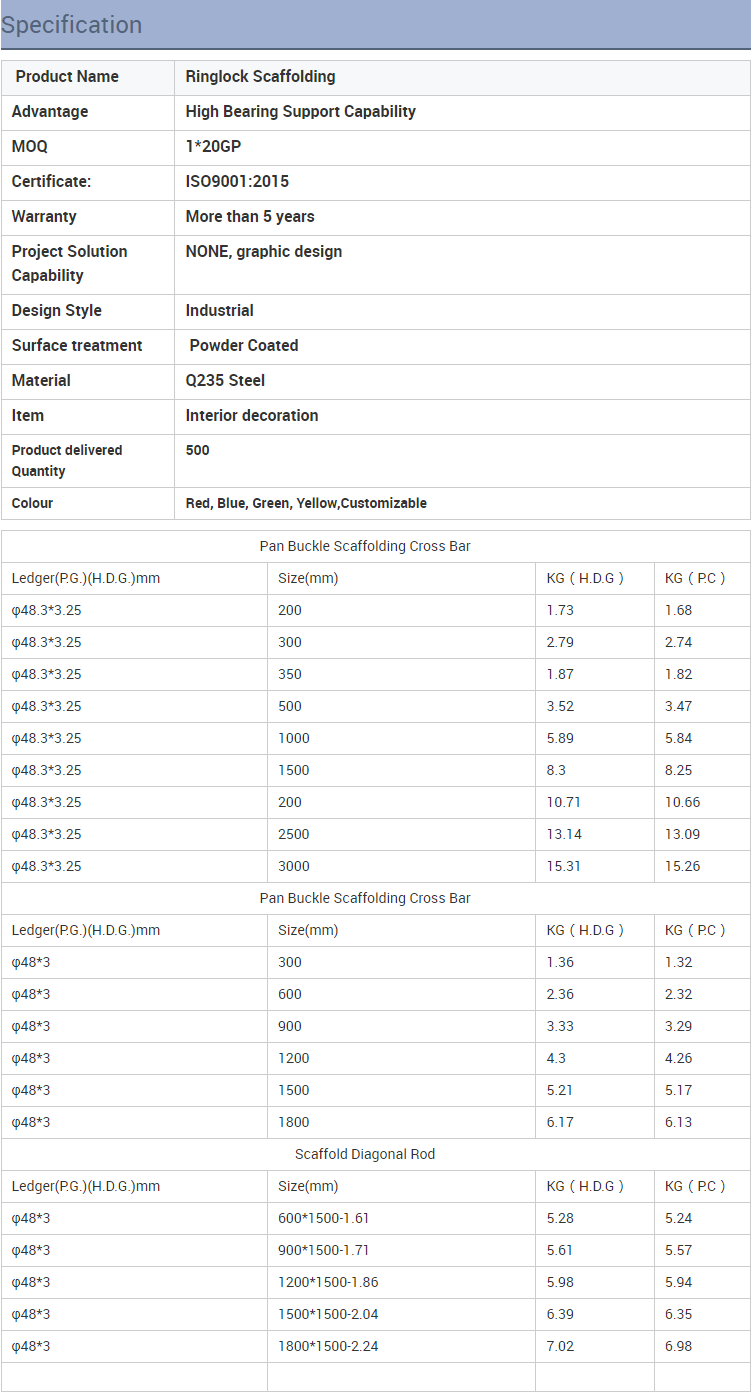

Ringlock Scaffolding is a straight tubular scaffold, is the most popular scaffold in the construction market, also known as Layher scaffold (because the basic theory of this scaffold is invented by German Layher company) the scaffold uses φ 48*3.25mm, Q345B high-strength steel pipe.

Description

Product name: steel ringlock scaffolding system

Material: Q235/Q345 Steel

Surface treatment: Hot Dip Galvanized, Painted

Color: Silver, blue, red, yellow, Customer Requirements

Component: Standard Ledger, Diagonal Brace, Board Bracket

Length: 0.5-3 m

Life span: More than 15 years

Certificate: ISO

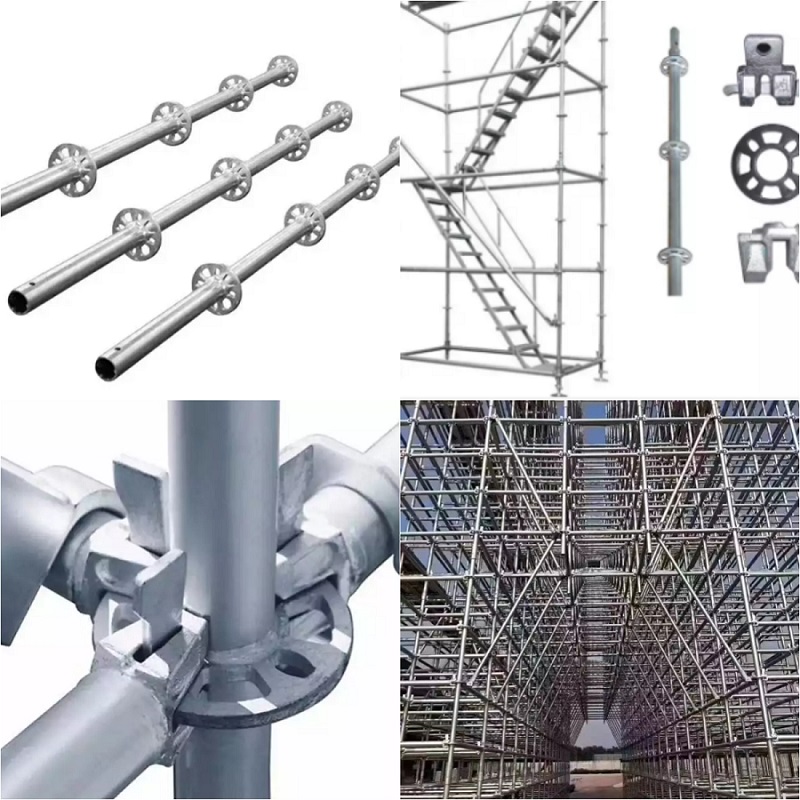

Ringlock scaffolding is a highly versatile modular scaffolding system used in construction for creating safe, durable, and efficient working platforms. It consists of standardized components such as vertical poles (standards), horizontal beams (ledgers), and locking rings that connect the system at multiple points for added stability. Known for its flexibility, strength, and rapid assembly, Ringlock scaffolding is widely used on high-rise buildings, industrial projects, and complex infrastructure sites.

Modular and Flexible: Ringlock scaffolding is made up of components that can be easily assembled to create a scaffold that adapts to the shape and structure of the building. Whether you need a straight scaffold for a high-rise construction or a complex structure for industrial projects, Ringlock can be adjusted to meet your needs.

Strong and Durable: The locking ring connectors create secure joints that withstand heavy loads, making this system ideal for large-scale and heavy-duty construction projects.

Quick Assembly: Scaffolding Ringlock System is easy to install with minimal labor. The components lock together quickly, reducing setup time and improving overall project efficiency.

Structure, The rosette plate at the joint point is a round plate with φ 122mm and 10mm thick, and 8 holes are pressed out in total, and then connected by 4 platforms and 4 diagonal supports.

In addition, it can be assembled with steel plates and beams to form a fully functional ring locking scaffold system.

Safety and Stability: The secure connections of the Ringlock system provide enhanced safety for workers at height, ensuring the scaffold remains stable even under challenging conditions.

Adaptability: Whether working on tall buildings, bridges, or complex architectural designs, the modularity of Ringlock scaffolding allows it to be used in a wide range of applications.

Cost-Efficiency: Because it's easy to assemble, disassemble, and reuse, Ringlock scaffolding offers a cost-effective solution for both short-term and long-term construction projects.

High-Rise Building Construction: With its high load-bearing capacity, Ringlock scaffolding is ideal for high-rise buildings, providing secure support as construction progresses vertically.

Industrial Projects: The adjustable nature of Ringlock scaffolding makes it perfect for industrial sites, where complex and large-scale structures need robust support.

Infrastructure Projects: Bridges, tunnels, and stadiums often require adaptable scaffolding, which makes Ringlock scaffolding the go-to solution for these large and intricate constructions.

Feature Ringlock Scaffolding Connection Point Rosette (ring) with eight connection slots Versatility Highly versatile; excels with complex, curved, or irregular structures. Assembly Speed Generally faster due to the simple wedge-locking mechanism. Bracing Allows for more extensive and multi-directional bracing. Applications High-rise buildings, bridges, large industrial plants, stadiums. Load Bearing Excellent load-bearing capacity and structural integrity.

FAQ and Package Shipping

FAQ

Q1. What is the advantage of your company?

A1. Our company has a professional team and a professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. The logo and the color can be customized?

A3. Yes, we welcome you to sample custom.

Q4. Any other good service your company can provide?

A4. Yes, we can provide good after-sale and fast delivery.

Min. order : 1 piece samples

Lead time:

| Quantity(pieces) | 1 - 1000 | > 1000 |

| Est. time (days) | 45 | To be negotiated |

Graphic customization(Min. order 1000 pieces)